Features

Auto Bag Feeding Packing Machine:

1. Main machine; 2. 10-nozzle weighter; 3. Z type auto-loader; 4. Frame.

Performance features:

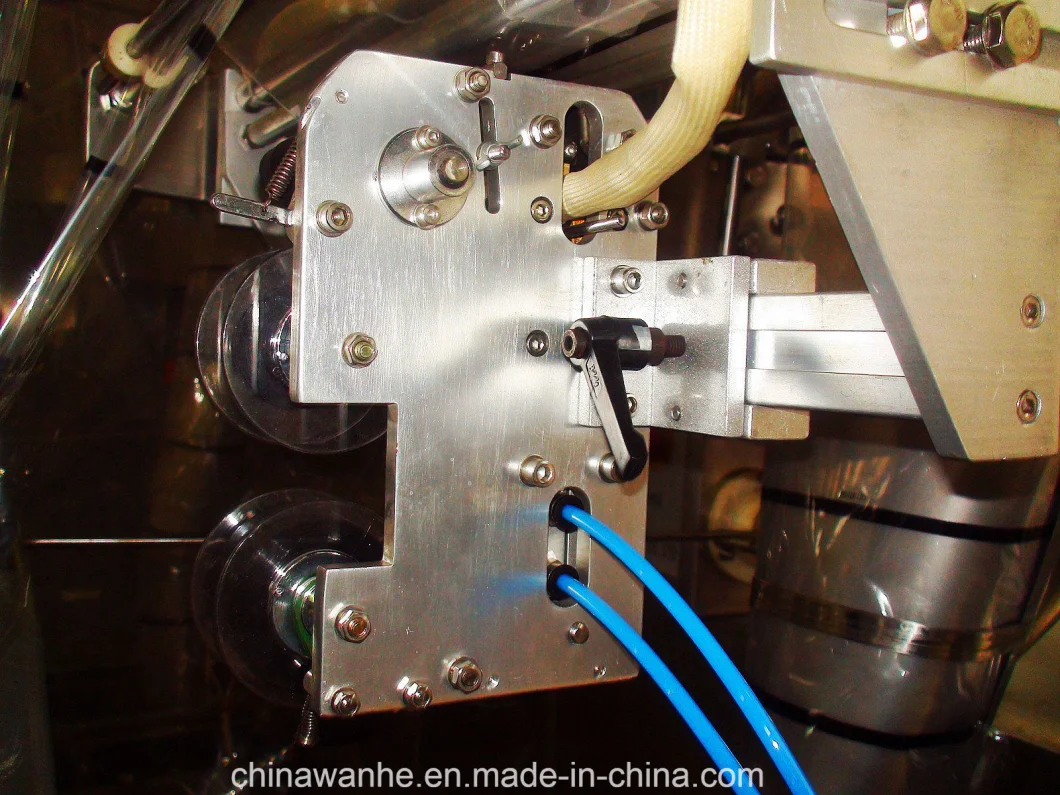

1. The whole production process including feeding, automatic bag taking, coding, opening, quantitative filling, heat sealing and finished product output can be completed automatically.

2. The intelligent combination scale adopts advanced PLC and pod (touch screen) operation interface, which is easy to operate, high precision, fast speed and stable performance.

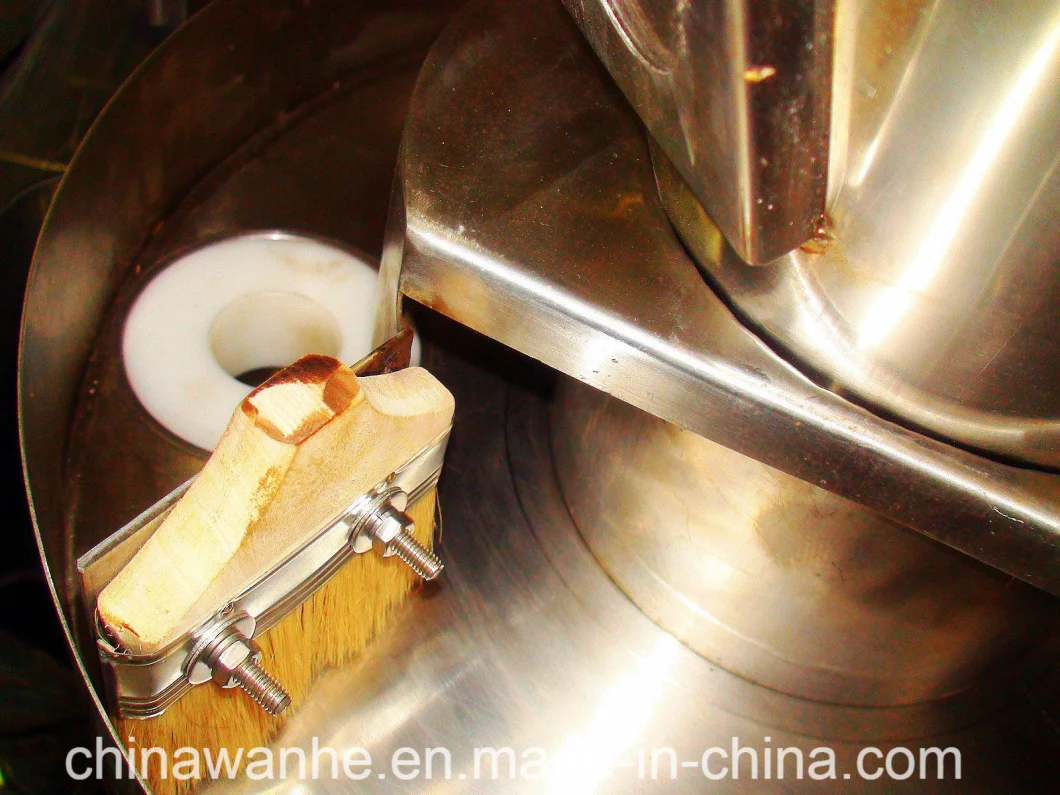

3. Automatic detection function: if the bag is not opened or the bag is incomplete, the bag can be reused without feeding and heat sealing, and the waste can be avoided and the production cost can be saved for users.

4. The width of bag is controlled by motor. Press and hold the control button to adjust the width of each group of clamps, which is easy to operate and save time.

5. Safety device: when the working air pressure is abnormal or the heating pipe is in fault, the alarm will be given.

6. In accordance with the unsanitary standards of food processing machinery, stainless steel or other materials meeting the food hygiene requirements are used for processing when contacting with materials or packaging bags on the machine to ensure food hygiene and safety standards, and packaging of anti-corrosion chemical products is required.

7. The packaging range is wide. By selecting different meters, it can be applied to the packaging of liquid, granule, paste, powder, irregular block and other materials.

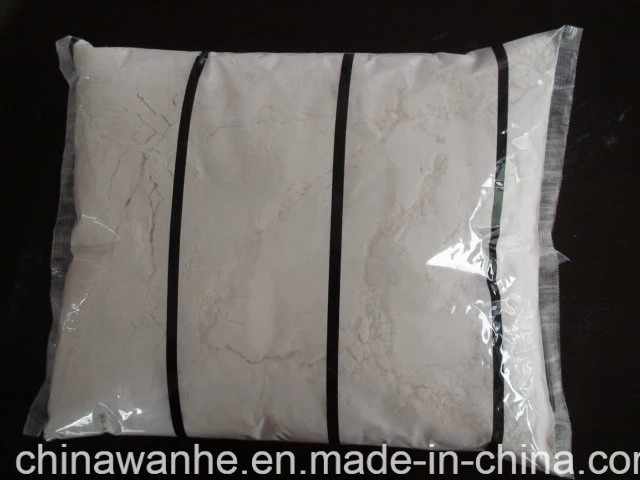

8. It can pack multi-layer composite film, polyester / polyethylene, polyester / aluminum foil / polyethylene, polyester / aluminum plating / polyethylene, paper / polyethylene, with a wide range of packaging.

| Model | HL8-200K |

| Bag Types | Stand bag, hand bag, zipper bag, four side sealing bag, three side sealing bag, paper bag, etc |

| Size | W:80~200mm L:80-300mm |

| Filling range | 10-1500g |

| Speed | 45-60bags/mins(Depending on the product) |

| accuracy | ≤±1% |

| Powder | 4KW |

| Application Range | rozen (potato chips, dumplings) chicken powder, monosodium glutamate, melon seeds, red dates, hot pot seasoning, tea, seeds, betel nut, candy, potato chips, Cereals, preserves, chocolate, coffee beans, biscuits, peanuts, cakes, puffed food and other solid materials, strip, spherical and irregular shape. |

| Optional | Computer combination scale, material conveyor and working platform |

| Work Flow | Eight stations: 1. Bag loading 2. Printing production date 3. Opening bag 4. Blanking 5. Blanking 6. Poking or vibration 7. Heat sealing 8. Shaping and output |

Samples:

BBBFDOf