CH-ST-1 Single Line High Speed T-shirt Bag making machine

Specifications:

* The specification are subject to be changed for improvement without notice.

To make printed or non-printed t-shirt bags / shopping bags from layflat tubes.

Material: HDPE,LDPE, bio-degradable(Corn Starch) material.

Computer controlled, Servo motor control, Automatic length fixing system.

Integrated progress / One-step solution / Automatic production: Material feeding-conveying-Bottom sealing-cutting-punching.

2 servo motor system, computerized control system, LPC display, Panasonic photo electric eye tracking system, easy to operate.

2 Lines of printed bags can be made at the same time.

Imported frequency converter to regulate speed.

automatic feeding system.

Automatic punching and folding system(double folds).

Conveyor to transport the finished products.

Pneumatic lifting feeding frame to feed film rolls, Air expansion core shaft.Efficient rolling devices.

Blow air discharge system, bag bottom integrating function. Uniformed bag stacks and accurate punching is guaranteed.

Imported cutter heated by dependent circuit heating system.High precision temperature control system.

IC electronic control system. Socket-pin inserting design, easy to change the parts.

Automatic stop on material zero-feeding, Material breaking and material jamming.

Features

Computer control over the entire process

Integrated process flows from film roll to final bag

Servo motor as standard configuration . Easy to adjust bag length and the production speed

Components self-testing function available

Automatic film feeding, Non- tension adjustment Coordination

Automatically stop when running out of film

Automatically stop when film feeding blocks or bags jam

Automatically stop when color tracking is lost

High production efficiency, Cost saving and Time saving solution

Our service:

1.Guarantee period: 5 year Garantee for Screw, from the date customers receive the machine.

lifetime warranty for after-sales service and mechanical parts.

2.Delivery:within 35-40days finish production,we start to manufacture the machine after we receiving 30% of the payment as deposit.

3.Packing: Film Wrap

4. After sale service:

We can arrange engineer to install the machine and training worker, but customers need to pay the charges, including flight tickets cost, accomodation cost, salary USD/day.

Free installation, ajustment and training for consumers purchase more than $100000 only

5.Professional advices and consultancy for the relating machines in 24 hours.

Feel Free to contact us.

Iris

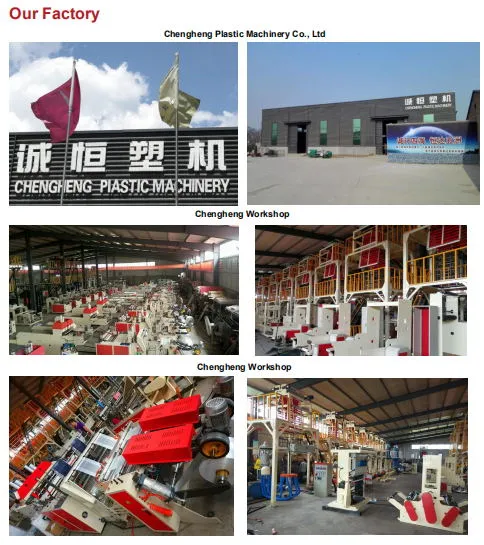

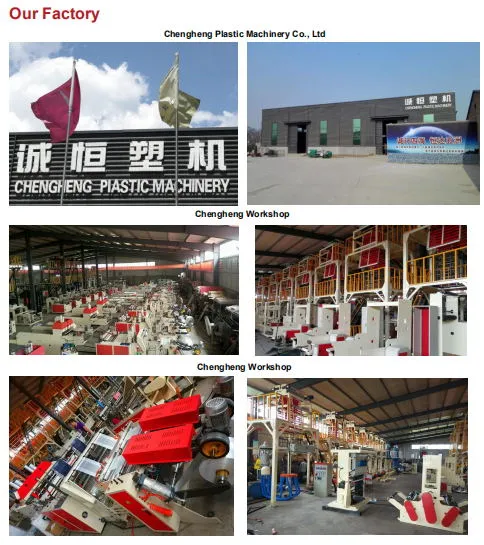

Chengheng Plastic Machinery Co., Ltd

Cell / : +86151 3015 0201

Landline +86 319 5797 567

website: chengheng27.en.made-in-china.com

Address: Qiao Jia Zhai Plastic Industry Zone,

Ning Jin County, Hebei Province,

PRC

Ningjin Chengheng Plastic Machinery Co., Ltd.

A Manufacturer of Blown Film Extrusion Machinery and Bag Making Machinery

We have more than 15 years of experiences in plastic processing and plastic packaging machinery products.

In the past 15 years we have been building plastic machines for clients from all over the world.

Our products

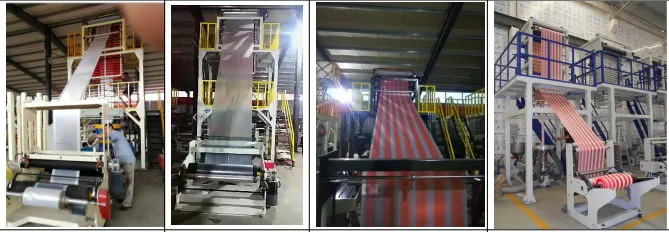

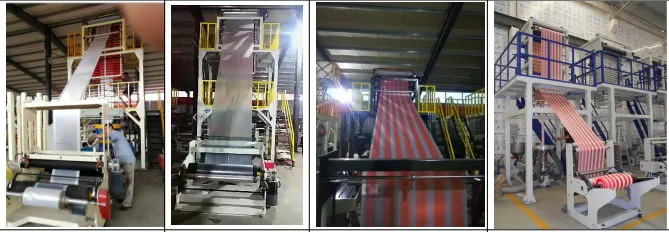

Our Blown Film Extrusion Machine

Our AUtomatic Bag making Machine

We have gained CE, SGS, or BV certificates for most of our products.

SGS and TUV audited plant. Golden member of Made-in-China and Alibaba.com

The factory is located in Ningjin Plastic industrial zone in North China, out of Shijiazhuang city, hebei province, about 2 hours driving south of Beijing airport.

Specifications:

| Model | CH-ST-1/600 | CH-ST-1/950 |

| Bag Width | 200-500mm | 300-800mm |

| Bag Length | 300-800mm | 600-1200mm |

| Bag Thickness | 0.01-0.05mm | 0.01-0.05mm |

| Bag-making Speed | 300pcs/min | 300pcs/min |

| Air Pressure | 6HP | 8HP |

| Main Power | 7.5kw | 9.5kw |

| Weight | 1500kg | 2000kg |

| Overall Dimension | 7000×1500×1800mm | 7000×1800×1800mm |

* The specification are subject to be changed for improvement without notice.

To make printed or non-printed t-shirt bags / shopping bags from layflat tubes.

Material: HDPE,LDPE, bio-degradable(Corn Starch) material.

Computer controlled, Servo motor control, Automatic length fixing system.

Integrated progress / One-step solution / Automatic production: Material feeding-conveying-Bottom sealing-cutting-punching.

2 servo motor system, computerized control system, LPC display, Panasonic photo electric eye tracking system, easy to operate.

2 Lines of printed bags can be made at the same time.

Imported frequency converter to regulate speed.

automatic feeding system.

Automatic punching and folding system(double folds).

Conveyor to transport the finished products.

Pneumatic lifting feeding frame to feed film rolls, Air expansion core shaft.Efficient rolling devices.

Blow air discharge system, bag bottom integrating function. Uniformed bag stacks and accurate punching is guaranteed.

Imported cutter heated by dependent circuit heating system.High precision temperature control system.

IC electronic control system. Socket-pin inserting design, easy to change the parts.

Automatic stop on material zero-feeding, Material breaking and material jamming.

Features

Computer control over the entire process

Integrated process flows from film roll to final bag

Servo motor as standard configuration . Easy to adjust bag length and the production speed

Components self-testing function available

Automatic film feeding, Non- tension adjustment Coordination

Automatically stop when running out of film

Automatically stop when film feeding blocks or bags jam

Automatically stop when color tracking is lost

High production efficiency, Cost saving and Time saving solution

Our service:

1.Guarantee period: 5 year Garantee for Screw, from the date customers receive the machine.

lifetime warranty for after-sales service and mechanical parts.

2.Delivery:within 35-40days finish production,we start to manufacture the machine after we receiving 30% of the payment as deposit.

3.Packing: Film Wrap

4. After sale service:

We can arrange engineer to install the machine and training worker, but customers need to pay the charges, including flight tickets cost, accomodation cost, salary USD/day.

Free installation, ajustment and training for consumers purchase more than $100000 only

5.Professional advices and consultancy for the relating machines in 24 hours.

Feel Free to contact us.

Iris

Chengheng Plastic Machinery Co., Ltd

Cell / : +86151 3015 0201

Landline +86 319 5797 567

website: chengheng27.en.made-in-china.com

Address: Qiao Jia Zhai Plastic Industry Zone,

Ning Jin County, Hebei Province,

PRC

Ningjin Chengheng Plastic Machinery Co., Ltd.

A Manufacturer of Blown Film Extrusion Machinery and Bag Making Machinery

We have more than 15 years of experiences in plastic processing and plastic packaging machinery products.

In the past 15 years we have been building plastic machines for clients from all over the world.

Our products

- Blown film extrusion machine, co-extrusion blown film machine. For 1-5 layers blown film made of LDPE, LLDPE, HDPE, OPP, PP, (bio) degradable plastics, recycled material and blends.

- Bag making machine. For flat bags, Vest(T-shirt) bags, string drawing bags, Garbage bags, carry bags, roll bags, (Courier)permanent adhesive bags, laminated bags.

- Plastic film printing machine. Plastic Laminating machine.

Our Blown Film Extrusion Machine

Our AUtomatic Bag making Machine

We have gained CE, SGS, or BV certificates for most of our products.

SGS and TUV audited plant. Golden member of Made-in-China and Alibaba.com

The factory is located in Ningjin Plastic industrial zone in North China, out of Shijiazhuang city, hebei province, about 2 hours driving south of Beijing airport.